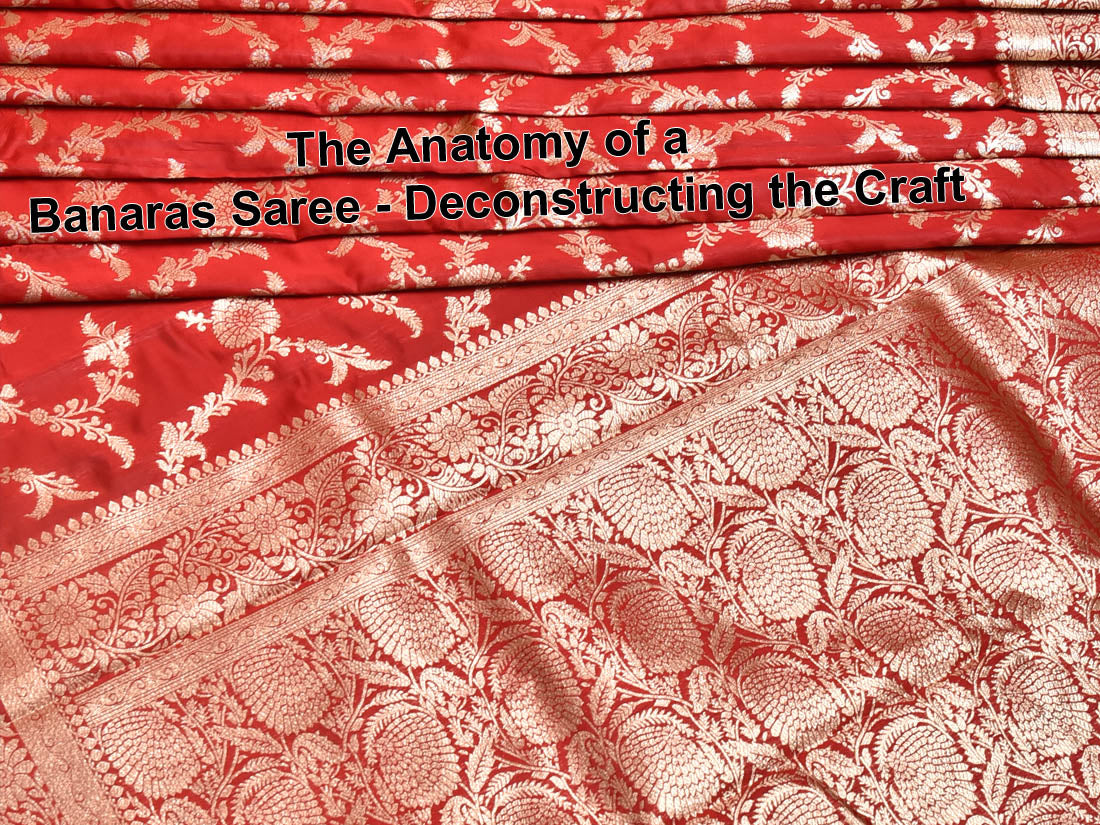

The Anatomy of a Banaras Saree - Deconstructing the Craft

The Anatomy of a Banaras Saree - Deconstructing the Craft

The creation of a Banarasi saree is a testament to meticulous skill, precious materials, and ancient techniques passed down through generations. Understanding the components of its construction—the fabric, the thread, and the weave—is essential to appreciating its value and artistry.

The Canvas: From Katan to Kora

The foundation of any Banarasi saree is its fabric, with several distinct types offering different textures, drapes, and aesthetics.

· Katan (Pure Silk): Considered the finest and most traditional choice, Katan is a plain-weave fabric made from pure mulberry silk. It is created by twisting together silk filaments to produce a yarn that is exceptionally sturdy and durable, yet remarkably soft and light.15 Its luxurious texture, graceful drape, and inherent sheen make it the quintessential fabric for bridal and heirloom sarees.16

· Kora (Organza): Kora silk is a thin, sheer, plain-weave fabric known for its weightlessness and crisp texture.15 Woven from thinly spun silk threads, its almost-see-through nature, coupled with the glamorous sheen of silk, creates an ethereal and fluid drape. Kora Banarasi sarees are often chosen for festive and formal occasions where a lighter feel is desired.16

· Georgette/Chiffon: Named after a 20th-century French dressmaker, Georgette is a sheer, lightweight crêpe fabric made with highly twisted yarns, which give it a characteristic crinkly surface.15 Handwoven Banarasi Khaddi Georgette is particularly prized for its rich use of

zari and its easy-to-drape quality.17 Chiffon is a similar, even lighter fabric, offering an airy and flowing silhouette.16

· Tussar: A type of wild silk, Tussar is valued for its rich, coarse texture and natural, deep golden hue.15 It is known for being a cooler and more breathable fabric, making it a comfortable yet elegant choice for various occasions.16

· Other Fabrics: The Banarasi weaving tradition also incorporates other materials, including Dupion, a crisp silk with characteristic lumps or "slubs" in the yarn; Chanderi, a blend of silk and cotton (Sico) known for its lightness and suitability for summer; and Tissue, a delicate, translucent fabric woven with a high concentration of metallic thread in the weft to create a shimmering, golden-cloth effect.15

The Shimmering Soul: The Art and Science of Zari

The defining feature of a Banarasi saree is its zari work, the intricate patterns woven with metallic threads. The quality of the zari is a key determinant of the saree's value and longevity.

· Real Zari: The traditional and most prized form of zari is a product of a laborious and costly process. It begins with bricks of 98% pure silver, which are melted and drawn into fine wires.18 These wires are then flattened into thin strips and meticulously wrapped around a core yarn, typically of pure silk.13 These spools of silver-wrapped thread are then electroplated with gold to create the final golden

zari.13 The composition is precise; a standard unit known as a "mark" (245 grams) traditionally contains 191 grams of silver, 51.55 grams of silk, and 2.45 grams of gold.13 This use of precious metals gives real

zari a soft, dignified glow and ensures it ages beautifully, making it suitable for heirloom pieces.

· Imitation and Metallic Zari: To make sarees more affordable, modern alternatives have been developed. Imitation zari replaces the pure silver wire with a copper alloy wire that is then electroplated with silver.13 This significantly reduces the cost while retaining a metallic look.

Metallic zari, the most common modern version, uses a metallized polyester film slit into fine strips and wrapped around a core yarn. It is lightweight, non-tarnishing, and durable, but it often has a harsher, brighter shine and lacks the soft luster and heirloom quality of real zari.13

The Weaver's Hand: A Lexicon of Techniques

The value hierarchy of Banarasi sarees is directly tied to the labor intensity and technical complexity of the weaving method. The choice of technique is the primary determinant of a saree's cost, production time, and status as a luxury item.

· Kadhwa (or Kadha Hua): Meaning "embroidered," Kadhwa is the most intricate, time-consuming, and revered Banarasi weaving technique.20 In this method, each individual motif is woven separately into the fabric by hand using extra spools of thread called

tilli. This is distinct from techniques where a shuttle runs from end to end. The process often requires two weavers working simultaneously on the loom. The result is a raised, embossed pattern that is sharply defined, with no loose threads or floats on the reverse side of the saree.20 This meticulous process allows for a stunning variety of colors and textures within a single saree and can take anywhere from 15 days to over six months to complete.6

· Phekwa (or Cutwork): A more common and less labor-intensive technique, Phekwa involves weaving the supplementary weft yarn (for the motifs) from one end of the fabric to the other.20 This creates long "floats" of thread on the reverse side of the saree between the motifs. Once the weaving is complete, these excess floating threads are manually cut, giving the technique its other name, "Cutwork".17 While still beautiful, this method is significantly faster and less expensive than Kadhwa.

· Kadiyal (or Korvai): This ancient three-shuttle weaving technique is used to create sarees with solid, contrasting borders.20 The body of the saree and its two borders are woven with separate shuttles of different colored yarns. The weaver skillfully interlocks the threads of the body and the border at the join, creating a sharp, clean demarcation of color. This hallmark of high-quality handloom weaving is also found in other famous Indian textiles like Kanjeevaram and Paithani sarees.20

· Tanchoi: Believed to have been brought to India from China by three brothers with the surname "Choi" (hence Tan-choi, or "three Chois"), this is a highly intricate weaving technique.20 It uses one or two warp threads and multiple colored weft threads to create complex, all-over patterns, often featuring floral, geometric, or animal motifs. The result is a fabric with a satin-like texture and an embossed appearance, which is remarkably soft and has no loose threads on the back.8

· Meenakari: This technique involves the addition of colorful resham (silk) threads alongside the zari to fill in the details of motifs.20 It creates a vibrant, multi-hued, enameled effect, similar to the Meenakari work found in jewelry, adding depth and richness to the design.8

A connoisseur can thus understand a saree's value not just by its beauty but by deconstructing its anatomy—recognizing that a Kadhwa weave is inherently more valuable than a Phekwa weave, and real zari is superior to metallic. This technical knowledge transforms appreciation from purely aesthetic to deeply informed.

|

Technique Name |

Meaning/Origin |

Weaving Process |

Visual Characteristic (Front) |

Visual Characteristic (Reverse) |

Time/Cost Implication |

|

Kadhwa |

"Embroidered" |

Each motif is individually hand-woven with extra spools (tilli). |

Raised, embossed, sharply defined motifs. |

Clean finish with no loose threads or floats. |

Highest; very labor-intensive (15 days to 9+ months). |

|

Phekwa/Cutwork |

"Thrown" shuttle |

Supplementary weft runs from end to end, creating motifs together. |

Motifs are woven into the fabric. |

Long floating threads between motifs are manually cut. |

Lower; faster production time than Kadhwa. |

|

Kadiyal/Korvai |

"Interlocking" |

Three shuttles are used to weave the body and two borders separately. |

Solid, sharply contrasting borders. |

A fine line of interlocked threads where colors meet. |

High; requires immense skill and precision. |

|

Tanchoi |

"Three Chois" (Chinese origin) |

One or two warps with multiple colored wefts create dense patterns. |

Intricate, all-over patterns with a satin-like, embossed feel. |

Smooth finish with no floats. |

High; technically complex and intricate. |

|

Meenakari |

"Enameling" |

Colorful silk threads (resham) are used in addition to zari to fill details. |

Multi-colored, jewel-like effect within motifs. |

Colored threads visible on the reverse within the motif area. |

Adds complexity and cost to the base weave. |